I. Introduction

The rotary cylinder is an important part of the excavator, which plays the role of carrying and rotating the fuselage. In the excavator, the rotary cylinder is usually installed between the bottom of the fuselage and the chassis, and the rotation of the fuselage is realized through it.

The importance of the rotary cylinder lies in its ability to make the excavator work more flexibly and efficiently. By rotating the oil cylinder, the excavator can move the excavation part to the desired position without moving the body, thus greatly improving the work efficiency. In addition, the rotary actuator can also allow the excavator to rotate flexibly in a narrow space, avoiding the situation that it cannot be operated due to the narrow working environment.

In short, the rotary actuator is one of the indispensable and important parts of the excavator. Its function and importance have a vital impact on the working efficiency and scope of the excavator.

This article will discuss and discuss the working principle of the rotary union, the determinants of the selection of the rotary cylinder by the excavator, the application in the excavator, the maintenance and maintenance of the rotary cylinder, etc.

II. Basic knowledge of excavator rotary cylinder

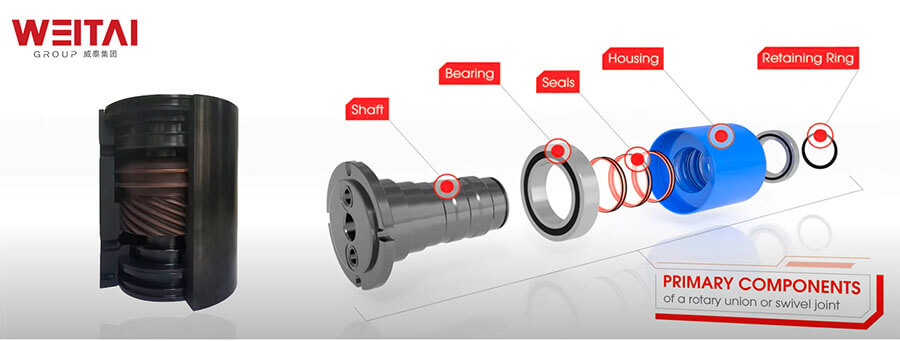

- Definition and construction of the rotary actuator

A rotary cylinder is a hydraulic actuator used to control the rotary motion of a machine. It usually consists of a cylinder barrel, cylinder head, piston oil port, and other components.

The cylinder body is the main part of the rotary cylinder, which is generally made of high-strength steel and can withstand high pressure and high torque loads. The cylinder head is used to seal one end of the cylinder body and to mount the rotating parts on it. The piston is a component that connects the cylinder body and the cylinder head and is responsible for converting hydraulic energy into mechanical energy, thereby achieving rotational motion. The oil port is used to connect the pipeline of the hydraulic system to provide hydraulic energy for the rotary cylinder.

The structure of the rotary actuator is divided into two types: unit type and compound type. The unit-type rotary cylinder consists of a pair of cylinder bodies and cylinder heads, which can meet the small torque and speed requirements. The compound rotary cylinder is composed of two or more unit rotary cylinders, which can withstand greater torque and speed requirements.

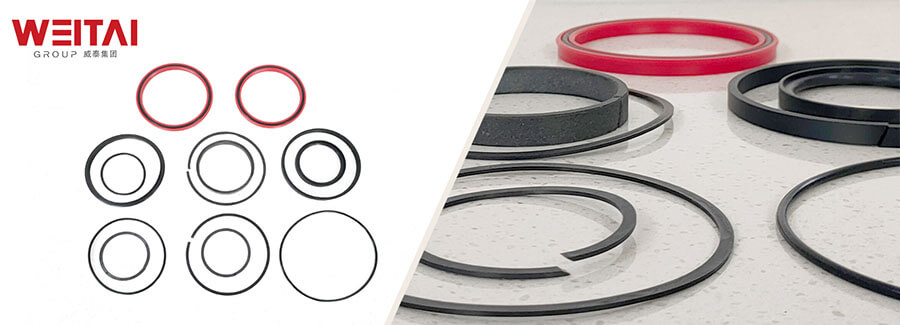

In addition, to improve the working efficiency and safety of the rotary actuator, other auxiliary components are usually added to its structure, such as shock-absorbing pads, seals, protective covers, etc. These components can effectively protect the rotary cylinder, prolong its service life, and improve work efficiency and safety.

- How the rotary cylinder works in an excavator and what it does in an excavator.

Rotary actuators are used in excavators to assist in the movement of booms, sticks, and buckets. These actuators work by converting hydraulic pressure into rotary motion, allowing the excavator to move its attachments in different directions.

In excavators, the rotary actuator is usually mounted on the boom or arm of the machine. Hydraulic fluid is fed into the actuator through hydraulic hoses, which causes the piston to move within the actuator. As the piston moves, it rotates a shaft attached to the boom or arm.

The amount of rotational force generated by the actuator can be controlled by adjusting hydraulic pressure and flow. This gives the operator precise control over the movement of the excavator's attachments.

Rotary actuators are commonly used in excavators because they provide a lot of power in a compact and lightweight package. They can also be designed to run at high speeds, which is very important for the efficient operation of excavators.

The swing cylinder plays an important role in the operation of an excavator because it allows the operator to easily position the boom and bucket for efficient digging and loading. It also helps increase the versatility of the excavator, as it allows the boom to be swiveled to access hard-to-reach areas and work around obstacles. In general, the slewing cylinder is a key component for the efficient operation of the excavator.

III. Selection Factors of Excavator Swivel Cylinder

load capacity:

It is very important to choose a rotary actuator with the proper load capacity to ensure that the excavator can handle various types and sizes of loads. The load capacity is usually expressed in the form of torque or weight, so it is necessary to know the maximum load of the excavator and choose a rotary actuator with sufficient load capacity.

speed:

Excavators require quick response and high speeds to increase productivity and efficiency. Therefore, it is very important to choose a rotary actuator with an appropriate speed. The speed is usually expressed in the unit of rotation angle or time. It is necessary to consider the operating requirements of the excavator and choose a rotary actuator with an appropriate speed.

Accuracy:

When performing fine operations, such as the control of excavation depth, position, and direction, it is necessary to choose a rotary actuator with high precision to ensure accuracy and control. Accuracy is usually expressed in the form of angle or position deviation, and a rotary actuator with appropriate accuracy needs to be selected according to the operation requirements of the excavator.

Temperature:

Small and medium excavators often operate in harsh environments, including high or low temperatures. Therefore, it is very important to choose a rotary actuator with an appropriate temperature range to ensure its reliability and long life. It is necessary to understand the temperature conditions of the excavator's working environment and choose a rotary actuator with an appropriate temperature range.

Reliability:

Excavators need to be used frequently, so it is crucial to choose a rotary actuator with high reliability and long life. The build quality, design, and materials of the rotary actuator need to be considered to ensure its long-term operation and reliability. In addition, a reputable and experienced supplier needs to be selected to ensure high-quality rotary actuators.

Safety:

The safety of excavator operation is always very important. Therefore, choosing a rotary actuator with safety features can ensure safe machine operation. For example, some rotary actuators may have safety features such as overload protection and limit switches, and a rotary actuator with appropriate safety features needs to be selected according to the application and operation requirements of the excavator.

Cost:

The last important selection factor is cost. Small and medium excavators need to choose a rotary actuator with an appropriate price to ensure that the total cost of the machine is controlled within the budget. Need to consider the price, performance, and quality of the rotary actuator and choose the best rotary actuator. In addition, it is necessary to weigh the choice of the high-performance rotary actuator and control the cost

IV. Application of rotary cylinder for small and medium excavators

- Application scenarios of rotary actuators for small and medium excavators.

The rotary cylinder is an important part of the excavator, which is usually used to achieve excavation, shoveling, and lifting. Here are some common application scenarios:

Digging: Digging is one of the main functions of an excavator. The rotary cylinder realizes the excavation of materials such as soil and stones by controlling the bucket of the excavator. During the excavation operation, the excavator will adjust the angle and direction of the excavator bucket through the rotation of the cylinder, to accurately excavate objects of the required depth and shape.

Shoveling: In addition to digging, shoveling is also one of the main functions of an excavator. Shoveling requires the assistance of a rotating cylinder. By controlling the direction and angle of the bucket, the excavator can scoop up objects and put them into the transport vehicle. In this process, the angle and direction adjustment of the rotary cylinder is very important, so that the bucket can better collect objects.

Lifting: Excavators can also be used for simple lifting operations, such as moving construction materials or loading and unloading goods. By rotating the cylinder, the excavator can adjust the angle and direction of its bucket for better handling of objects. In addition, the boom of the excavator can also control the height and direction by rotating the cylinder, making the lifting operation more precise and safe.

In general, rotary actuators play a vital role in applications such as excavation, shoveling, and lifting. It can control the angle and direction of the bucket and boom of the excavator, to realize the efficient completion of various work tasks.

-Specific attributes and requirements required for rotary cylinders in different scenarios, and how to choose the most suitable rotary cylinder.

Different work tasks have different requirements and specific attributes for small and medium excavator rotary cylinders. The following are specific requirements for rotary actuators for digging, shoveling, and lifting:

Digging: In digging operations, the rotating cylinder needs to have sufficient torque and speed to control the angle and direction of the bucket. In addition, the oil cylinder needs to have the characteristics of wear resistance, corrosion resistance, and high-pressure resistance to work in complex terrain and harsh environments.

Shoveling: Shoveling requires a high degree of precision and stability of the rotary cylinder for better handling of objects. Additionally, the swing cylinders require high torque and speed to adjust the direction and angle of the bucket. At the same time, cylinders need to be durable, wear-resistant, and corrosion-resistant for long-term use in shoveling operations.

Lifting: In lifting operations, rotary cylinders require high torque and precise control to adjust the angle and orientation of buckets and booms. In addition, cylinders need to have sufficient weight capacity to handle objects safely. At the same time, rotary cylinders need to be resistant to wear, corrosion, and high pressure for long-term use in heavy lifting operations.

How to choose the most suitable rotary actuator?

When selecting a rotary cylinder, the following factors need to be considered:

Working Tasks

It is necessary to choose a rotary cylinder according to different working tasks to meet different needs.

Load-bearing Capacity

It is necessary to choose a rotary cylinder with sufficient load-bearing capacity to safely handle objects.

Control Accuracy

It is necessary to choose a rotary actuator with high-precision control capabilities to better control the angle and direction of the bucket and boom.

Durability

It is necessary to choose a rotary cylinder with the characteristics of wear resistance, corrosion resistance, and high-pressure resistance so that it can be used for a long time in complex terrain and harsh environments.

V. Care and Maintenance of Rotary Cylinders

Maintenance and maintenance are very important to the reliability and performance of small and medium excavator rotary cylinders. Here are some common maintenance and maintenance practices:

Regularly check and replace oil seals and seals. Oil seals and seals are critical components in preventing oil leakage and contamination and must remain intact.

Check and change the oil. The oil should be changed regularly to ensure it is clean stable and suitable for the specific working environment of the rotary actuator.

Check and clean dirt and debris from the surface of the rotary cylinder. This debris can damage the surface and internal parts of the cylinder, causing performance degradation or failure.

Check and replace the filter screen inside the cylinder. The filter screen can prevent impurities from entering the cylinder and filter tiny particles in the oil to ensure clean and stable oil.

Check and adjust the sealing and lubrication system of the oil cylinder. The sealing and lubrication system of the oil cylinder needs to be checked and adjusted regularly to ensure its proper functioning.

Lubricate regularly. Lubricating oil reduces friction and wear, extending the life of the rotary cylinder.

Regularly check and replace the internal parts of the cylinder. The internal parts of the rotary cylinder require regular inspection and replacement to ensure its performance and reliability.

Maintenance and maintenance are very important to the reliability and performance of small and medium excavator rotary actuators. Regular maintenance and maintenance can extend the life of the rotary cylinder, and reduce failure and repair costs. Before using a rotary cylinder, be sure to understand and follow the recommendations and directions in the manufacturer's use and maintenance manual.

VI. Some practical advice to help you choose the right swivel cylinder.

Determine load requirements. Different applications require rotary cylinders with different torques and speeds. Selecting the correct swing cylinder requires knowing the desired load requirements, including maximum torque and speed.

Determine the working environment. Different working environments require rotary actuators with different materials and sealing requirements. For example, a rotary cylinder operating in a wet or corrosive environment requires stainless steel or an anti-corrosion coating.

Choose the appropriate installation method. Swivel cylinders can be installed horizontally or vertically. Installation space and support capacity need to be considered.

Consider the controls. Swivel cylinders can be controlled electrically, hydraulically or pneumatically. A control method suitable for the application needs to be selected.

Choose reliable brands and suppliers. Choosing a reliable brand and supplier can ensure the quality and after-sales service of the rotary cylinder.

Consider the balance of cost and performance. Selecting the proper rotary cylinder requires balancing cost and performance considerations. The lowest-cost rotary actuators may not be the best choice as they may not have adequate performance and reliability.

Pay attention to safety. When choosing a rotary cylinder, safety factors need to be considered, such as the protection device of the rotary cylinder and the safety of the control system.

In conclusion, when choosing a rotary cylinder, factors such as the load requirements of the application, working environment, installation method, control method, brand and supplier, cost and performance balance, and safety need to be considered. Selecting the correct swing cylinder can ensure reliability and performance for your application.

Summarize

Selecting the correct swing cylinder is critical to the reliability and performance of your excavator. An improperly fitted swing cylinder could result in erratic operation of the excavator, insufficient load-bearing capacity, or damage or failure of the swing cylinder in harsh operating environments. Therefore, choosing the correct rotary actuator is the key to ensuring the long-term reliability and high performance of the excavator.

When choosing a rotary cylinder, there are many factors to consider, such as load requirements, working environment, installation method, control method, brand and supplier, cost and performance balance, safety, etc. Only after these factors have been fully considered can the most suitable rotary cylinder be selected to ensure that it can meet the requirements of the excavator application.

In addition, it is also very important to choose reliable brands and suppliers. Only choosing a rotary cylinder from a proven brand and reliable supplier can ensure its quality and reliability of after-sales service.

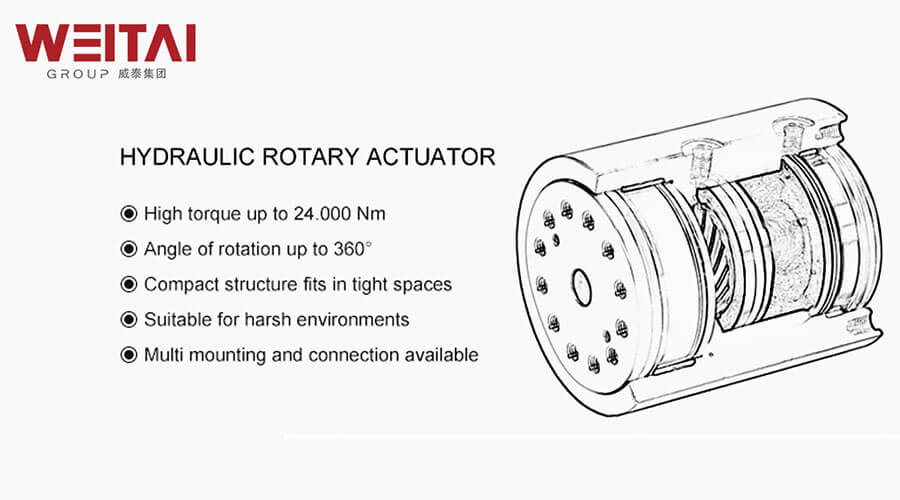

Weitai Group is committed to providing excellent hydraulic products and services to both businesses and final users worldwide. Starting from the production of OEM Hydraulic cylinders for North American Customers, we have grown to be an integrated company of manufacturing, trading, and investing. The hydraulic rotary actuator is one of our main products. Our factory is ISO certified and our material suppliers have all obtained CE, RoHS, CSA and UL certificates. We can design and customize according to drawings to meet the diverse needs of customers.