In order to effectively reduce workers’ compensation compensation and improve route efficiency, garbage truck equipment manufacturers began to try to improve the design of their products. An equipment manufacturer in the United States has designed and manufactured a dumpster tipping device for use with garbage trucks, recycling trucks and other types of waste handling equipment.

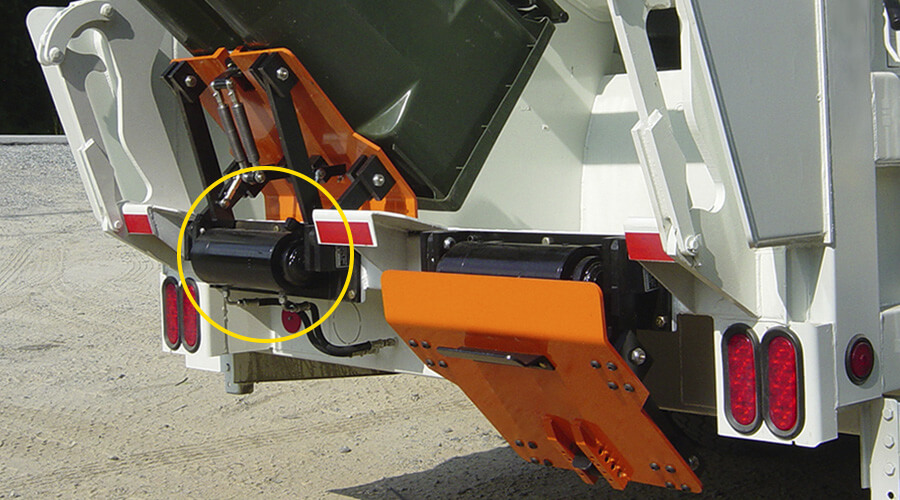

The tipping mechanism is installed on the front or side of the vehicle, and can also be installed on the large garbage bin of a front-loading garbage truck. When the operator places the trash can cart on the dumping equipment, the dumping equipment can lift the trash can and then tilt the barrel to dump the contents into the trash can. After dumping is completed, the tipping mechanism returns to its original position. The core component of the tipping mechanism is the hydraulic rotary actuator.

After the hydraulic rotary actuator rotates 220 degrees, the dumping angle becomes an acute angle, which is full of momentum and can completely empty the garbage. The base of the fixed hydraulic rotary actuator has a through hole through which accessories can be connected to the fixed plate of the tipping bucket mechanism. The base is not flush with the helical rotary actuator housing, but is located at both ends of the housing. In this way, part of the casing of the rotary actuator is located under the fixed plate, thereby improving the compactness of the device. The output shaft is splined at both ends of the component to facilitate matching and installation with the internal splines welded on the main arm of the tipping mechanism.

“So, how does the helical hydraulic rotary actuator work more efficiently? The following two cross-sectional views can clearly show you its working principle.”

Equipped with a helical hydraulic rotary actuator, the dump mechanism dumps more efficiently and completely, allowing garbage truck manufacturers to build equipment with high performance levels without the need for hydraulic cylinders. In fact, the tipping mechanism driven by the hydraulic cylinder cannot rotate more than 180 degrees, and the design is more complicated. The shape of the spiral swing cylinder can also be designed to be thinner, making it easier for the operator to control the unloading hopper. The design of the spiral swing cylinder is simple and compact. It is fixed on the tipping mechanism device through bolts and is flush with the body. It looks very stable and low-key, and has no exposed parts.

Compared with other rotating devices and actuator designs, the advantages of the helical hydraulic rotary actuator are also obvious: the structure is very compact and the output torque is extremely high; the torque at both ends of the output shaft is equal; there is a large-diameter tapered roller bearing inside to support the output shaft; Smooth operation, no drift, positive position (and almost zero clearance); no exposed moving parts; the spiral gear design has extraordinary impact resistance to load overloading or frequent movements with large impact forces; the overall rotation angle is constant speed, Constant torque rotation; at the same time, installation operations are cleaner and simpler.

In addition, the working flow requirements of the tipping mechanism equipped with a helical hydraulic rotary actuator are also smaller. Typically, the hydraulic system of a garbage truck operates at a pressure of about 210 bar (3000 psi) and a flow rate of about 75 to 300 l/min (20 to 80 gpm). After equipped with a spiral swing cylinder, the working flow requirement of the tipping mechanism is less than 8 l/min (2 gpm). The existing pressure oil circuit is connected to the hydraulic rotary actuator of the tipping mechanism through a diverter valve. The obtained flow can be adjusted and used to control the tipping bucket. mechanism, and the remaining flow is delivered to the compaction blade. The system is designed to minimize back pressure and heat generation, thereby extending the life of the oil and system.

Helical hydraulic rotary actuators are used in almost all aspects. Garbage truck manufacturers can use this to design compact and powerful tipping mechanisms. Trash cans and hanging bucket-type tipping mechanisms are also widely used. This can not only reduce workers’ compensation, improve route efficiency, and increase The large route range reduces the burden on staff, improves street sanitation, and helps create a cleaner and healthier urban environment!